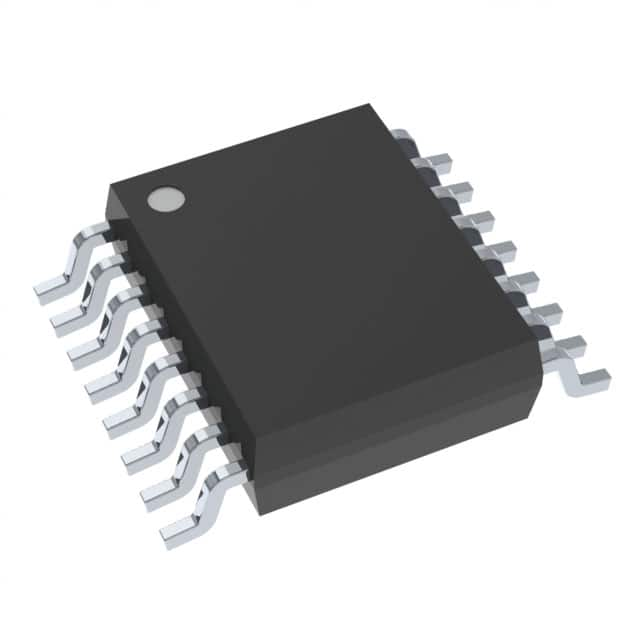

I-LM46002AQPWPRQ1 iphakheji ye-HTSSOP16 yesekethe ehlanganisiwe ye-IC chip ingxenye yoqobo yoqobo yama-electronics

Izimfanelo Zomkhiqizo

| UHLOBO | DESCRIPTION |

| Isigaba | Izifunda Ezihlanganisiwe (ICs) |

| Mfr | Texas Instruments |

| Uchungechunge | Ezezimoto, i-AEC-Q100, SIMPLE SWITCHER® |

| Iphakheji | I-Tape & Reel (TR) Cut Tape (CT) I-Digi-Reel® |

| SPQ | 2000T&R |

| Isimo somkhiqizo | Iyasebenza |

| Umsebenzi | Isinyathelo-Phansi |

| Ukucushwa Kokukhiphayo | Okuhle |

| I-Topology | Buck |

| Uhlobo Lokukhiphayo | Kuyalungiseka |

| Inombolo Yemiphumela | 1 |

| I-Voltage - Okokufaka (Okuncane) | 3.5V |

| I-Voltage - Okokufaka (Ubukhulu) | 60V |

| I-Voltage - Okukhiphayo (Okuncane/Okulungisiwe) | 1V |

| I-Voltage - Okukhiphayo (Ubukhulu) | 28V |

| Okwamanje - Okukhiphayo | 2A |

| Imvamisa - Ukushintsha | 200kHz ~ 2.2MHz |

| I-synchronous Rectifier | Yebo |

| Izinga Lokushisa Lokusebenza | -40°C ~ 125°C (TJ) |

| Uhlobo Lokukhweza | INtaba Engaphezulu |

| Iphakheji / Ikesi | 16-TSSOP (0.173", 4.40mm Ububanzi) Iphedi Eliveziwe |

| Iphakheji Yedivayisi Yomhlinzeki | 16-HTSSOP |

| Inombolo Yomkhiqizo Eyisisekelo | LM46002 |

Inqubo yokukhiqiza i-chip

Inqubo ephelele yokwenza ama-chip ihlanganisa ukuklanywa kwe-chip, ukukhiqizwa kwe-wafer, ukupakishwa kwe-chip, nokuhlolwa kwe-chip, phakathi kwayo inqubo yokukhiqiza i-wafer eyinkimbinkimbi kakhulu.

Isinyathelo sokuqala ukuklama kwe-chip, okusekelwe ezidingweni zokuklama, njengezinjongo zokusebenza, ukucaciswa, ukuhlelwa kwesekethe, ukuvuthwa kwezintambo kanye nemininingwane, njll. "Imidwebo yokuklama" iyakhiqizwa;ama-photomasks akhiqizwa kusengaphambili ngokwemithetho ye-chip.

②.Ukukhiqizwa kwe-wafer.

1. Ama-wafer ama-silicone asikwa abe ubukhulu obudingekayo kusetshenziswa i-wafer slicer.Uma i-wafer iba mncane, izindleko zokukhiqiza ziyancipha, kodwa inqubo idinga kakhulu.

2. ukumboza i-wafer surface ngefilimu ye-photoresist, ethuthukisa ukumelana ne-oxidation nezinga lokushisa.

3. Ukuthuthukiswa kwe-wafer photolithography kanye ne-etching kusebenzisa amakhemikhali azwela ukukhanya kwe-UV, okungukuthi athambile lapho echayeke ekukhanyeni kwe-UV.Ukuma kwe-chip kungatholakala ngokulawula ukuma kwe-mask.I-photoresist isetshenziswa ku-wafer ye-silicon ukuze izoncibilika lapho kuvezwe ukukhanya kwe-UV.Lokhu kwenziwa ngokusebenzisa ingxenye yokuqala ye-mask ukuze ingxenye evezwe ukukhanya kwe-UV ihlakazeke futhi le ngxenye encibilikisiwe ingase igezwe nge-solvent.Le ngxenye encibilikisiwe ingase igezwe nge-solvent.Ingxenye esele ibe isimise okwe-photoresist, isinika ungqimba lwe-silica olufunekayo.

4. Ukujova ama-ion.Ngokusebenzisa umshini wokufaka i-etching, izicupho ze-N kanye ne-P zifakwe ku-silicon engenalutho, futhi ama-ion ajovwe ukuze enze i-PN junction (isango le-logic);ungqimba lwensimbi olungaphezulu lube seluxhunywa kusekethe ngamakhemikhali kanye nemvula yesimo sezulu esibonakalayo.

5. Ukuhlolwa kwe-wafer Ngemva kwalezi zinqubo ezingenhla, kwakheka i-lattice yedayisi ku-wafer.Izici zikagesi zefa ngalinye zihlolwa kusetshenziswa ukuhlolwa kwephini.

③.Ukupakishwa kwe-chip

I-wafer eqediwe ilungisiwe, iboshelwe kumaphini, futhi yenziwa amaphakheji ahlukahlukene ngokuya ngesidingo.Izibonelo: DIP, QFP, PLCC, QFN, njalo njalo.Lokhu kunqunywa kakhulu imikhuba yohlelo lokusebenza yomsebenzisi, indawo yohlelo lokusebenza, isimo semakethe, nezinye izici ezizungezile.

④.Ukuhlolwa kwe-chip

Inqubo yokugcina yokukhiqiza i-chip isiqedile ukuhlolwa komkhiqizo, okungahlukaniswa ngokuhlolwa okuvamile nokuhlolwa okukhethekile, okokuqala ukuhlola izici zikagesi ze-chip ngemva kokupakishwa ezindaweni ezihlukahlukene, njengokusetshenziswa kwamandla, isivinini sokusebenza, ukumelana nogesi, njll. Ngemuva kokuhlolwa, ama-chips ahlukaniswa ngamamaki ahlukene ngokuya nezici zawo zikagesi.Ukuhlolwa okukhethekile kusekelwe kumingcele yezobuchwepheshe yezidingo ezikhethekile zekhasimende, futhi amanye ama-chips avela ekucacisweni okufanayo nezinhlobonhlobo ayahlolwa ukuze kubonakale ukuthi angakwazi yini ukuhlangabezana nezidingo ezikhethekile zekhasimende, ukuze kunqunywe ukuthi ama-chips akhethekile kufanele akhelwe ikhasimende.Imikhiqizo ephumelele uhlolo olujwayelekile ilebula ngokucaciswa, izinombolo zemodeli, nezinsuku zasembonini futhi iyapakishwa ngaphambi kokuphuma embonini.Ama-chips angaphumeleli ukuhlolwa ahlukaniswa njengawehlisiwe noma anqatshiwe kuye ngamapharamitha awazuzile.

.png)