Izingxenye ze-Semiconductors Electronic TPS7A5201QRGRRQ1 I-Ic Chips BOM Isevisi yokuthenga indawo eyodwa

Izimfanelo Zomkhiqizo

| UHLOBO | DESCRIPTION |

| Isigaba | Izifunda Ezihlanganisiwe (ICs) |

| Mfr | Texas Instruments |

| Uchungechunge | Ezezimoto, AEC-Q100 |

| Iphakheji | I-Tape & Reel (TR) Cut Tape (CT) I-Digi-Reel® |

| SPQ | 3000T&R |

| Isimo somkhiqizo | Iyasebenza |

| Ukucushwa Kokukhiphayo | Okuhle |

| Uhlobo Lokukhiphayo | Kuyalungiseka |

| Inombolo Yabalawuli | 1 |

| I-Voltage - Okokufaka (Ubukhulu) | 6.5V |

| I-Voltage - Okukhiphayo (Okuncane/Okulungisiwe) | 0.8V |

| I-Voltage - Okukhiphayo (Ubukhulu) | 5.2V |

| I-Voltage Dropout (Ubukhulu) | 0.3V @ 2A |

| Okwamanje - Okukhiphayo | 2A |

| I-PSRR | 42dB ~ 25dB (10kHz ~ 500kHz) |

| Lawula izici | Nika amandla |

| Izici Zokuvikela | Ngaphezulu Kwezinga Lokushisa, Reverse Polarity |

| Izinga Lokushisa Lokusebenza | -40°C ~ 150°C (TJ) |

| Uhlobo Lokukhweza | INtaba Engaphezulu |

| Iphakheji / Ikesi | 20-VFQFN Iphedi Eveziwe |

| Iphakheji Yedivayisi Yomhlinzeki | 20-VQFN (3.5x3.5) |

| Inombolo Yomkhiqizo Eyisisekelo | I-TPS7A5201 |

Uhlolojikelele lwama-chips

(i) Yini i-chip

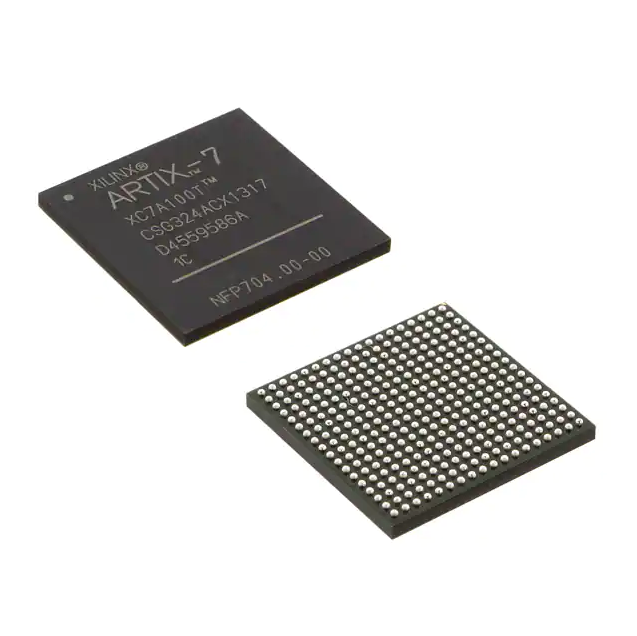

Isekethe ehlanganisiwe, efushanisiwe njenge-IC;noma i-microcircuit, i-microchip, i-chip iyindlela yokwenza amasekhethi amancane (ikakhulukazi amadivaysi e-semiconductor, kodwa futhi izingxenye ze-passive, njll.) kuma-electronics, futhi ngokuvamile akhiqizwa ebusweni be-semiconductor wafers.

(ii) Inqubo yokukhiqiza i-chip

Inqubo ephelele yokwenziwa kwe-chip ihlanganisa ukuklanywa kwe-chip, ukwenziwa kwe-wafer, ukwenziwa kwephakheji, nokuhlola, phakathi kwayo inqubo yokwenziwa kwe-wafer eyinkimbinkimbi kakhulu.

Okokuqala ukuklama kwe-chip, ngokwezidingo zokuklama, "iphethini" ekhiqizwayo, impahla eluhlaza ye-chip yi-wafer.

I-wafer yenziwe nge-silicon, ecwengisiswe esihlabathini se-quartz.I-wafer iyingxenye ye-silicon ehlanjululwe (99.999%), bese i-silicon ehlanzekile yenziwe ibe yizinduku ze-silicon, eziba yinto yokukhiqiza ama-semiconductors e-quartz yamasekethe ahlanganisiwe, anqunywe abe ama-wafer okukhiqiza ama-chip.Uma i-wafer iba mncane, izindleko zokukhiqiza ziyancipha, kodwa inqubo idinga kakhulu.

I-wafer enamathela

I-wafer coating imelana ne-oxidation nokumelana nezinga lokushisa futhi iwuhlobo lwe-photoresist.

Ukuthuthukiswa kwe-Wafer Photolithography kanye nokunamathisela

Ukugeleza okuyisisekelo kwenqubo ye-photolithography kuboniswa kumdwebo ongezansi.Okokuqala, ungqimba lwe-photoresist lusetshenziswa ebusweni be-wafer (noma i-substrate) bese yomiswa.Ngemuva kokumisa, i-wafer idluliselwa emshinini we-lithography.Ukukhanya kudluliselwa kumaski ukuze kuveze iphethini kumaski ku-photoresist endaweni eyi-wafer, okuvumela ukuchayeka futhi kuvuselele ukusabela kwe-photochemical.Amawafa aveziwe abe esebhakwa okwesibili, okwaziwa ngokuthi ukubhaka kwangemuva kokuchayeka, lapho ukusabela kwe-photochemical kuphelele kakhulu.Ekugcineni, unjiniyela ufafazwa ku-photoresist endaweni eyi-wafer ukuze athuthukise iphethini eveziwe.Ngemuva kokuthuthukiswa, iphethini kumaski ishiywe ku-photoresist.

Ukunamathisela, ukubhaka, nokuthuthukisa konke kwenziwa kunjiniyela we-screed futhi ukuchayeka kwenziwa ku-photolithograph.Unjiniyela we-screed kanye nomshini we-lithography ngokuvamile kusetshenziswa emgqeni, ama-wafer adluliswa phakathi kwamayunithi nomshini kusetshenziswa irobhothi.Lonke uhlelo lokuchayeka nokuthuthukisa luvaliwe futhi amawafa awavezwa ngokuqondile endaweni ezungezile ukuze kuncishiswe umthelela wezingxenye eziyingozi endaweni ku-photoresist kanye nokusabela kwe-photochemical.

Doping nokungcola

Ukutshala ama-ion ku-wafer ukukhiqiza ama-semiconductors ohlobo lwe-P no-N ahambisanayo.

Ukuhlolwa kwe-wafer

Ngemuva kwalezi zinqubo ezingenhla, kwakhiwa i-lattice yedayisi ku-wafer.Izici zikagesi zedayizi ngayinye ziyahlolwa kusetshenziswa iphinikhodi.

Ukupakisha

Ama-wafers akhiqiziwe alungisiwe, aboshwe ngezikhonkwane, futhi enziwa amaphakheji ahlukene ngokuvumelana nezidingo, yingakho i-chip core efanayo ingahlanganiswa ngezindlela ezahlukene.Isibonelo, i-DIP, i-QFP, i-PLCC, i-QFN, njalonjalo.Lapha kunqunywa ikakhulukazi imikhuba yohlelo lokusebenza yomsebenzisi, indawo yohlelo lokusebenza, ifomethi yemakethe, nezinye izici ezizungezile.

Ukuhlola, ukupakisha

Ngemuva kwenqubo engenhla, ukukhiqizwa kwe-chip kuqedile.Lesi sinyathelo siwukuhlola i-chip, ukususa imikhiqizo enesici bese uyipakisha.

Ubudlelwano phakathi kwama-wafers nama-chips

I-chip yenziwe ngamadivaysi angaphezu kweyodwa e-semiconductor.Ama-Semiconductors ngokuvamile ama-diode, ama-triode, amashubhu womphumela wensimu, ama-resistors amandla amancane, ama-inductors, ama-capacitor, njalonjalo.

Kuwukusetshenziswa kwezindlela zobuchwepheshe zokushintsha ukuhlangana kwama-electron amahhala kuyinucleus ye-athomu emthonjeni oyindilinga ukuze kushintshwe izici ezibonakalayo ze-nucleus ye-athomu ukuze kukhiqizwe ukushaja okuhle noma okungalungile kwabaningi (ama-electron) noma ambalwa (izimbobo) ukuze yakha ama-semiconductors ahlukahlukene.

I-silicon ne-germanium yizinto ezisetshenziswa kakhulu ze-semiconductor futhi izakhiwo zazo nezinto ezisetshenziswayo zitholakala kalula ngamanani amakhulu futhi ngezindleko eziphansi zokusetshenziswa kulobu buchwepheshe.

I-silicon wafer yenziwe ngenani elikhulu lamadivayisi we-semiconductor.Umsebenzi we-semiconductor, yiqiniso, ukwakha isekethe njengoba kudingekile nokuba khona ku-silicon wafer.