Cabanga nje uphrinta i-smartphone ephelele, esebenza ngokugcwele ekhaya noma ehhovisi.Ukuphrinta kwe-3D(3DP), i-aka Additive Production (AM), ingachaza kabusha ifekthri yesikhathi esizayo njengedivayisi engabekwa kudeskithophu.

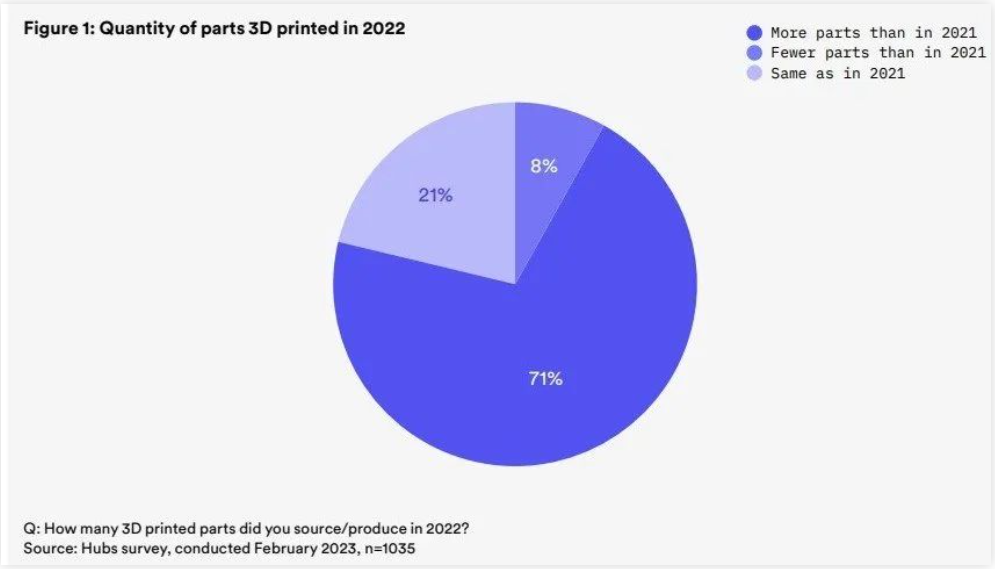

Kusenendlela ende okufanele ihanjwe, kodwa ukuphrinta kwe-3D sekuvele kusetshenziselwa ukukhiqiza imikhiqizo ye-elekthronikhi efanaizixhumi, amabhodi esekethe aphrintiwe, i-RFama-amplifiers, ilangaamamojula, izinto zikagesi ezishumekiwe nezindlu.Ngokombiko ohlanganiswe inkundla yokukhiqiza ye-inthanethi Hubs, intuthuko kubuchwepheshe bokuphrinta nezinto zokwakha isize ukuphrinta kwe-3D ukubona amandla ako emboni.

"Ukuphrinta kwe-3D njengemboni kusesimweni lapho abantu abaningi bezimisele ukuphrinta izingxenye ezisetshenziswayo," kusho uSam Manning, umkhulumeli we-Markforged, umenzi wamaphrinta we-3D wamaRandi ayizigidi eziyi-101."Lowo umehluko omkhulu kusukela eminyakeni emihlanu edlule."

Kuwo wonke umkhakha wokukhiqiza, ukuphrinta kwe-3D kuxazulula izinkinga eziningi eziqondene nomkhakha othile.Abakhiqizi akusadingeki bathembele kozakwethu baphesheya ukuze benze i-prototyping nokukhiqiza.Amadizayini angalandwa ngokuphephile ngokuqondile kuphrinta, kuncishiswe ubungozi bokuntshontshwa kwe-IP.Izingxenye zingakhiwa ngenani eliqondile elidingekayo ngesikhathi sokusetshenziswa.Lokhu kukhulula amabhizinisi ezimfuneko ze-oda elincane kanye nezikhathi zokuhola zokuthunyelwa/zokulethwa.Ngokwemibandela ye-supply chain, ukuphrinta kwe-3D "kuyi-booster yokukhiqiza efika ngesikhathi."

Eminyakeni embalwa edlule, i-Flex, umhlinzeki we-EMS womhlaba wonke ongu-$29.72 billion, yahlonza ukuphrinta kwe-3D njengensika yesu layo le-Industrial 4.0.Amaqembu okuklama kanye namaqembu akhiqizayo avame ukuba nemibono ehlukene mayelana nendlela yokwakha umkhiqizo.Ukwenziwa kwe-3D kuvala leli gebe ngokunikeza ama-prototypes asheshayo namamodeli.Njengoba umkhiqizo uthuthukiswa, ubuchwepheshe be-3D budala inqolobane yedijithali yesinyathelo ngasinye enqubweni.Izinguquko zedizayini zingafakwa ngokushesha futhi kwakhiwe imodeli entsha ye-3D.

Abakhiqizi baphinde babone izindleko kanye nezinzuzo zokusimama kokuphrinta kwe-3D.Imfucuza ephuma ezintweni ezingavuthiwe iye kumabhokisi ekhadibhodi iyaqedwa.I-inventory ayisadingi ukugcinwa futhi inakekelwe endaweni yokugcina impahla.Izindleko zokuthumela nokusabalalisa zincane.Ngokusho kwama-Hubs, i-process automation ithuthukisa isivinini sokuphrinta, ikhwalithi, nokungaguquguquki ngokusebenzisa i-slicer optimization, ukubeka izingxenye ezihlakaniphile, ukwakheka kwenqwaba, kanye nokucubungula ngemuva.

Ukusika kuyinqubo yokuguqula imodeli ye-3D ibe yisethi yemiyalelo yephrinta.

“Amafemu ngeke kusadingeka ukuthi ahlole i-inventory minyaka yonke ukuze aqiniseke ukuthi anezingxenye ezifanele esitokweni, noma azihlalele alinde uma kwenzeka ungenazo izingxenye ozidingayo,” kusho uManning."Iphethini manje ithi' thatha eyodwa, yenza eyodwa."

Inani elikhulayo lezixazululo zesoftware lixhuma futhi lizenzele ngokuzenzakalelayo izigaba ezahlukahlukene ochungechungeni lokukhiqiza lokuphrinta lwe-3D.I-Markforged isungule isoftware yayo.Ukugeleza komsebenzi okuzenzakalelayo ngokugcwele kunika amandla ukuphrinta kwe-3D okungagadiwe, nokugadwa okuncane komuntu okudingekayo efekthri.

"I-software yethu iqinisekisa ukuthi izingcezu zinembile futhi zilingisa ingxenye ngaphambi kokunyathelisa ukuze kuqinisekiswe amandla aqinile," kusho uManning."Ngaleyo ndlela, unenqolobane yedijithali yezingxenye."

Isikhathi sokuthumela: Aug-14-2023