Izingxenye Ze-elekthronikhi Uhlu Lwe-Circuit Bom Mcu TLC7733IDR LMR33630BQRNXRQ1 LM431CIM3/NOPB TMS320F28033PAGT IC Chip

Izimfanelo Zomkhiqizo

| UHLOBO | DESCRIPTION |

| Isigaba | Izifunda Ezihlanganisiwe (ICs) |

| Mfr | Texas Instruments |

| Uchungechunge | Ezezimoto, AEC-Q100 |

| Iphakheji | I-Tape & Reel (TR) |

| SPQ | 3000T&R |

| Isimo somkhiqizo | Iyasebenza |

| Umsebenzi | Isinyathelo-Phansi |

| Ukucushwa Kokukhiphayo | Okuhle |

| I-Topology | Buck |

| Uhlobo Lokukhiphayo | Kuyalungiseka |

| Inombolo Yemiphumela | 1 |

| I-Voltage - Okokufaka (Okuncane) | 3.8V |

| I-Voltage - Okokufaka (Ubukhulu) | 36V |

| I-Voltage - Okukhiphayo (Okuncane/Okulungisiwe) | 1V |

| I-Voltage - Okukhiphayo (Ubukhulu) | 24V |

| Okwamanje - Okukhiphayo | 3A |

| Imvamisa - Ukushintsha | 1.4MHz |

| I-synchronous Rectifier | Yebo |

| Izinga Lokushisa Lokusebenza | -40°C ~ 125°C (TJ) |

| Uhlobo Lokukhweza | I-Surface Mount, I-Flank Emanzi |

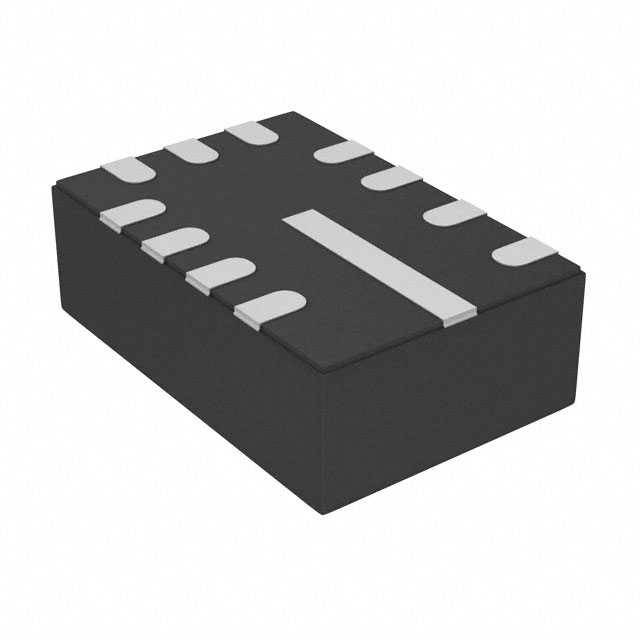

| Iphakheji / Ikesi | 12-VFQFN |

| Iphakheji Yedivayisi Yomhlinzeki | 12-VQFN-HR (3x2) |

| Inombolo Yomkhiqizo Eyisisekelo | I-LMR33630 |

1.Umklamo we-chip.

Isinyathelo sokuqala sokuklama, ukubeka okuhlosiwe

Isinyathelo esibaluleke kakhulu ekwakhiweni kwe-IC ukucaciswa.Lokhu kufana nokunquma ukuthi mangaki amagumbi nezindlu zangasese ozifunayo, yimaphi amakhodi wokwakha okudingeka uhambisane nawo, bese uqhubeka nomklamo ngemva kokuba usunqume yonke imisebenzi ukuze ungachithi isikhathi esengeziwe ekulungiseni okulandelayo;Idizayini ye-IC idinga ukudlula kunqubo efanayo ukuze kuqinisekiswe ukuthi i-chip ewumphumela ngeke ibe namaphutha.

Isinyathelo sokuqala sokucaciswa ukunquma injongo ye-IC, ukuthi kuyini ukusebenza, kanye nokusetha inkombandlela evamile.Isinyathelo esilandelayo ukubona ukuthi yiziphi izivumelwano okufanele zihlangatshezwe, njenge-IEEE 802.11 yekhadi elingenantambo, ngaphandle kwalokho i-chip ngeke ihambisane neminye imikhiqizo emakethe, okwenza kube nzima ukuxhuma kwamanye amadivaysi.Isinyathelo sokugcina siwukuthola ukuthi i-IC izosebenza kanjani, yabela imisebenzi ehlukene kumayunithi ahlukene kanye nokuthola ukuthi amayunithi ahlukene azoxhunywa kanjani elinye nelinye, ngaleyo ndlela kugcwalise imininingwane.

Ngemuva kokuklama imininingwane, sekuyisikhathi sokuklama imininingwane ye-chip.Lesi sinyathelo sifana nomdwebo wokuqala wesakhiwo, lapho uhlaka lulonke ludwetshwa khona ukuze kube lula imidwebo elandelayo.Endabeni yama-IC chips, lokhu kwenziwa ngokusebenzisa ulimi lokuchaza ihadiwe (i-HDL) ukuchaza isekethe.Ama-HDL afana ne-Verilog ne-VHDL avame ukusetshenziswa ukuveza kalula imisebenzi ye-IC ngekhodi yokuhlela.Khona-ke uhlelo luhlolelwa ukunemba futhi lulungiswe luze luhlangabezane nomsebenzi oyifunayo.

Izendlalelo zama-photomasks, anqwabelanisa i-chip

Okokuqala nje, manje sekuyaziwa ukuthi i-IC ikhiqiza ama-photomasks amaningi, anezendlalelo ezihlukene, ngayinye inomsebenzi wayo.Umdwebo ongezansi ubonisa isibonelo esilula se-photomask, kusetshenziswa i-CMOS, ingxenye eyisisekelo kakhulu kumjikelezo ohlanganisiwe, njengesibonelo.I-CMOS iyinhlanganisela ye-NMOS ne-PMOS, yakha i-CMOS.

Isinyathelo ngasinye esichazwe lapha sinolwazi lwaso olukhethekile futhi singafundiswa njengesifundo esihlukile.Isibonelo, ukubhala ulimi lokuchaza ihadiwe akudingi nje kuphela ukujwayelana nolimi lokuhlela, kodwa futhi nokuqonda ukuthi amasekhethi anengqondo asebenza kanjani, indlela yokuguqula ama-algorithms adingekayo abe yizinhlelo, nokuthi isofthiwe yokuhlanganisa iguqula kanjani izinhlelo zibe amasango anengqondo.

2.Iyini iwafa?

Ezindabeni ze-semiconductor, kuhlala kunezinkomba zendwangu ngokosayizi, njengendwangu engu-8" noma engu-12", kodwa yini ngempela i-wafer?Ibhekisela kuyiphi ingxenye ka-8"? Futhi ibuphi ubunzima bokukhiqiza amawafa amakhulu? Okulandelayo umhlahlandlela wesinyathelo ngesinyathelo wokuthi iyini i-wafer, isisekelo esibaluleke kakhulu se-semiconductor.

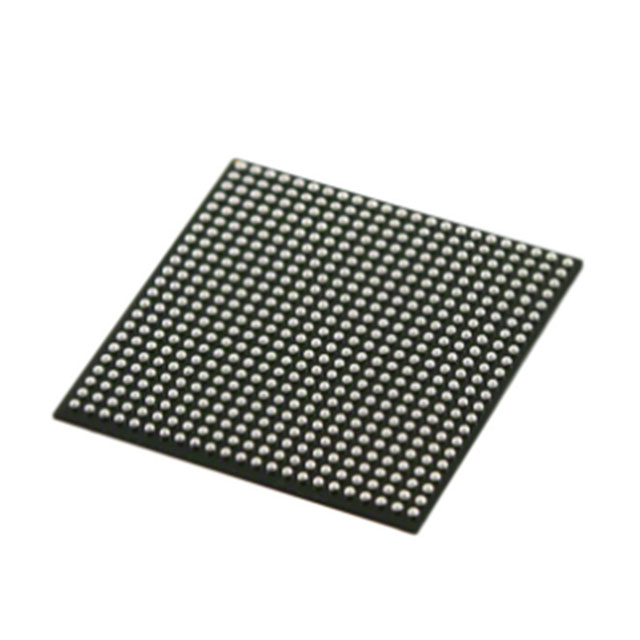

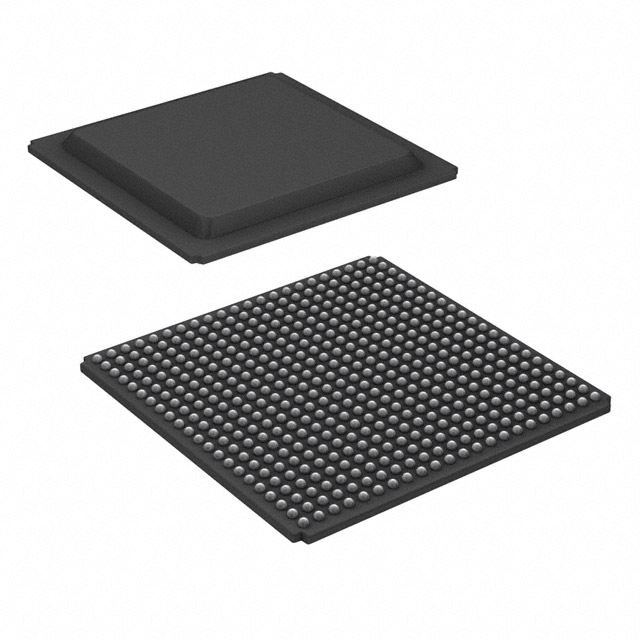

Ama-wafers ayisisekelo sokukhiqiza zonke izinhlobo zama-chip ekhompyutha.Singaqhathanisa ukukhiqizwa kwama-chip nokwakha indlu enamabhulokhi e-Lego, sinqwabelanise ungqimba ngemva kongqimba ukuze sakhe umumo oyifunayo (okungukuthi ama-chips ahlukahlukene).Kodwa-ke, ngaphandle kwesisekelo esihle, indlu ephumayo izobe igwegwile futhi ingabi ngokuthanda kwakho, ngakho-ke ukwenza indlu ephelele, i-substrate ebushelelezi iyadingeka.Endabeni yokukhiqiza ama-chip, le substrate iyisinkwa esincanyana esizochazwa ngokulandelayo.

Phakathi kwezinto eziqinile, kukhona isakhiwo esikhethekile se-crystal - i-monocrystalline.Inendawo yokuthi ama-athomu ahlelwa ngokulandelana ngokulandelana, okwenza indawo eyisicaba yama-athomu.Ngakho-ke ama-wafers e-Monocrystalline angasetshenziswa ukuhlangabezana nalezi zidingo.Kodwa-ke, kunezinyathelo ezimbili eziyinhloko zokukhiqiza impahla enjalo, okungukuthi ukuhlanzwa nokudonsa i-crystal, emva kwalokho impahla ingaqedwa.

.png)