Izingxenye Ze-elekthronikhi I-IC Chips Amasekethe Ahlanganisiwe IC TPS74701QDRCRQ1 indawo eyodwa yokuthenga

Izimfanelo Zomkhiqizo

| UHLOBO | DESCRIPTION |

| Isigaba | Izifunda Ezihlanganisiwe (ICs) |

| Mfr | Texas Instruments |

| Uchungechunge | Ezezimoto, AEC-Q100 |

| Iphakheji | I-Tape & Reel (TR) Cut Tape (CT) I-Digi-Reel® |

| Isimo somkhiqizo | Iyasebenza |

| Ukucushwa Kokukhiphayo | Okuhle |

| Uhlobo Lokukhiphayo | Kuyalungiseka |

| Inombolo Yabalawuli | 1 |

| I-Voltage - Okokufaka (Ubukhulu) | 5.5V |

| I-Voltage - Okukhiphayo (Okuncane/Okulungisiwe) | 0.8V |

| I-Voltage - Okukhiphayo (Ubukhulu) | 3.6V |

| I-Voltage Dropout (Ubukhulu) | 1.39V @ 500mA |

| Okwamanje - Okukhiphayo | 500mA |

| I-PSRR | 60dB ~ 30dB (1kHz ~ 300kHz) |

| Lawula izici | Nika amandla, amandla amahle, isiqalo esithambile |

| Izici Zokuvikela | Ngaphezulu Kwamanje, Ngaphezu Kwezinga Lokushisa, Isekhethi Emfishane, Ngaphansi Kwe-Voltage Lockout (UVLO) |

| Izinga Lokushisa Lokusebenza | -40°C ~ 125°C |

| Uhlobo Lokukhweza | INtaba Engaphezulu |

| Iphakheji / Ikesi | I-10-VFDFN Exposed Pad |

| Iphakheji Yedivayisi Yomhlinzeki | I-10-VSON (3x3) |

| Inombolo Yomkhiqizo Eyisisekelo | I-TPS74701 |

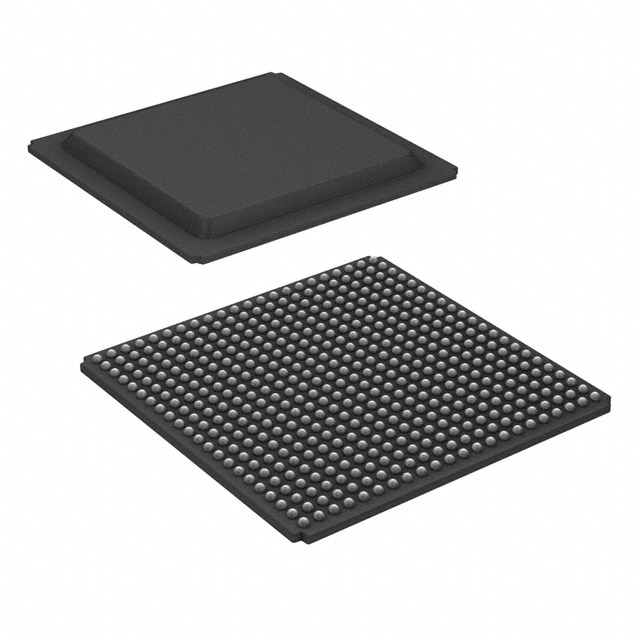

Ubudlelwano phakathi kwama-wafers nama-chips

Ukubuka konke kwama-wafers

Ukuze uqonde ubudlelwano phakathi kwama-wafers nama-chips, okulandelayo ukubuka konke kwezici ezibalulekile ze-wafer nolwazi lwe-chip.

(i) Yini isinkwa esilucwecwana

Ama-wafer ama-wafer e-silicon asetshenziswa ekukhiqizeni amasekethe ahlanganisiwe e-silicon semiconductor, abizwa ngokuthi ama-wafers ngenxa yokuma kwawo okuyisiyingi;zingacutshungulwa kuma-wafers e-silicon ukuze zakhe izinhlobonhlobo zezingxenye zesifunda futhi zibe yimikhiqizo yesekethe ehlanganisiwe enemisebenzi ethile kagesi.Izinto ezisetshenziswayo zama-wafers yi-silicon, futhi kukhona ukutholakala okungapheli kwe-silicon dioxide ebusweni boqweqwe lomhlaba.I-silicon dioxide ore icwengwa ezithandweni zikagesi ze-arc, i-chlorinated nge-hydrochloric acid futhi i-distilled ukuze ikhiqize i-polysilicon ehlanzekile enobumsulwa obungu-99.99999999999%.

(ii) Izinto zokusetshenziswa eziyisisekelo zamawafa

I-Silicon icwengwa kusuka esihlabathini se-quartz futhi ama-wafers ayahlanzwa (99.999%) kusuka ku-silicon yesici, ebese senziwa izinti ze-silicon eziba izinto zama-semiconductors e-quartz zamasekethe ahlanganisiwe.

(iii) Inqubo yokukhiqiza i-wafer

Ama-wafers ayizinto eziyisisekelo zokukhiqiza ama-semiconductor chips.Impahla eluhlaza ebaluleke kakhulu yamasekethe ahlanganisiwe we-semiconductor yi-silicon ngakho-ke ihambisana nama-wafers e-silicon.

I-silicon itholakala kakhulu emvelweni ngendlela yama-silicates noma i-silicon dioxide emadwaleni namatshe.Ukwenziwa kwama-silicon wafers kungafingqwa ngezinyathelo ezintathu eziyisisekelo: ukucwengwa kwe-silicon nokuhlanzwa, ukukhula kwe-silicon eyodwa ye-crystal, kanye nokwakheka kwe-wafer.

Esokuqala ukuhlanzwa kwe-silicon, lapho izinto ezingavuthiwe zesihlabathi namatshe zifakwa esithandweni somlilo se-arc kagesi ekushiseni okungaba ngu-2000 °C naphambi komthombo wekhabhoni.Emazingeni okushisa aphezulu, ikhabhoni ne-silicon dioxide esihlabathini nakumatshe kuhlangana nokusabela kwamakhemikhali (ikhabhoni ihlangana nomoya-mpilo, ishiye i-silicon) ukuze kutholakale i-silicon emsulwa enobumsulwa obungaba ngu-98%, eyaziwa nangokuthi i-silicon yebanga le-metallurgical, ihlanzekile ngokwanele kumadivayisi e-microelectronic ngoba izakhiwo zikagesi ze-semiconductor materials zizwela kakhulu ekugxilweni kokungcola.Ngakho-ke i-silicon yebanga le-Metallurgical iyahlanjululwa futhi: i-silicon yebanga le-metallurgical echotshoziwe ibhekana nokusabela kwe-chlorination nge-gaseous hydrogen chloride ukuze kukhiqizwe i-silane eyi-liquid, bese i-distilled futhi incishiswe ngamakhemikhali ngenqubo ekhiqiza i-polycrystalline silicon ehlanzekile enobumsulwa obungu-99.99999999999999 %, eba yi-electron grade silicon.

Okulandelayo kuza ukukhula kwe-silicon ye-monocrystalline, indlela evame kakhulu ebizwa ngokuthi ukudonsa okuqondile (indlela ye-CZ).Njengoba kuboniswe kumdwebo ongezansi, i-polysilicon ehlanzekile kakhulu ifakwa ku-quartz crucible futhi ishisiswe ngokuqhubekayo nge-heater ye-graphite ezungeze ngaphandle, igcina izinga lokushisa licishe libe ngu-1400 °C.Igesi esithandweni ngokuvamile ayisebenzi, okuvumela i-polysilicon ukuba incibilike ngaphandle kokudala ukusabela kwamakhemikhali okungafuneki.Ukwakha amakristalu awodwa, ukuqondiswa kwamakristalu kulawulwa futhi: i-crucible ijikeleziswa nge-polysilicon melt, ikristalu yembewu icwiliswa kuyo, futhi induku yokudweba iqhutshelwa ngakolunye uhlangothi ngenkathi idonsa kancane futhi iqonde phezulu. i-silicon iyancibilika.I-polysilicon encibilikisiwe inamathela phansi kwekristalu yembewu futhi ikhule ibheke phezulu ngasendleleni yokuhlelwa kwe-lattice yekristalu lembewu.