I-LCD entsha kanye neyangempela eSharp Display LM61P101 LM64P101 LQ10D367 LQ10D368 ONE SPOT BUY

Izimfanelo Zomkhiqizo

| UHLOBO | DESCRIPTION |

| Isigaba | Izifunda Ezihlanganisiwe (ICs) |

| Mfr | Texas Instruments |

| Uchungechunge | Ezezimoto, AEC-Q100 |

| Iphakheji | Ithubhu |

| SPQ | 2500T&R |

| Isimo somkhiqizo | Iyasebenza |

| Uhlobo Lokukhiphayo | Umshayeli we-Transistor |

| Umsebenzi | Isinyathelo-phezulu, Yehla |

| Ukucushwa Kokukhiphayo | Okuhle |

| I-Topology | Buck, Boost |

| Inombolo Yemiphumela | 1 |

| Izigaba Zokukhiphayo | 1 |

| I-Voltage - Supply (Vcc/Vdd) | 3V ~ 42V |

| Imvamisa - Ukushintsha | Kufika ku-500kHz |

| Umjikelezo Womsebenzi (Ubukhulu) | 75% |

| I-synchronous Rectifier | No |

| Ukuvumelanisa Iwashi | Yebo |

| I-Serial Interfaces | - |

| Lawula izici | Nika amandla, Ukulawula Imvamisa, Irempu, Isiqalo Esithambile |

| Izinga Lokushisa Lokusebenza | -40°C ~ 125°C (TJ) |

| Uhlobo Lokukhweza | INtaba Engaphezulu |

| Iphakheji / Ikesi | 20-PowerTSSOP (0.173", 4.40mm Ububanzi) |

| Iphakheji Yedivayisi Yomhlinzeki | 20-HTSSOP |

| Inombolo Yomkhiqizo Eyisisekelo | LM25118 |

1.Indlela yokwenza i-crystal wafer eyodwa

Isinyathelo sokuqala ukuhlanzwa kwe-metallurgical, okubandakanya ukwengeza i-carbon nokuguqula i-silicon oxide ku-silicon ye-98% noma ngaphezulu ubumsulwa usebenzisa i-redox.Izinsimbi eziningi, njengensimbi noma ithusi, zicwengisiswa ngale ndlela ukuze kutholwe insimbi emsulwa eyanele.Kodwa-ke, ama-98% awanele ekukhiqizeni ama-chip futhi kusadingeka ukuthuthukiswa okwengeziwe.Ngakho-ke, inqubo ye-Siemens izosetshenziselwa ukuhlanzwa okwengeziwe ukuze kutholwe i-polysilicon ephezulu yokuhlanzeka edingekayo kunqubo ye-semiconductor.

Isinyathelo esilandelayo ukudonsa amakristalu.Okokuqala, i-polysilicon ehlanzekile etholwe ngaphambili iyancibilika ukuze yakhe i-silicon ewuketshezi.Ngemva kwalokho, ikristalu eyodwa ye-silicon yembewu ihlanganiswa noketshezi olumanzi bese idonselwa phezulu kancane ngenkathi ijikeleza.Isizathu sesidingo sembewu eyodwa yekristalu ukuthi, njengomuntu oklelile, ama-athomu e-silicon adinga ukukleliswa ukuze labo abeza ngemva kwawo bazi ukuthi kufanele bahlele kanjani kahle.Ekugcineni, lapho ama-athomu e-silicon eseyishiyile indawo ewuketshezi futhi aqina, ikholomu ye-silicon eyodwa ehlelwe kahle iphelele.

Kodwa u-8" no-12" umeleni?Ukhuluma ngobubanzi bensika esiyikhiqizayo, ingxenye ebukeka njengomphini wepensela ngemva kokuba ubuso sebulungisiwe futhi busikwe baba amawafa amancane.Yibuphi ubunzima ekwenzeni amawafa amakhulu?Njengoba kushiwo ngaphambili, inqubo yokwenza ama-wafers ifana nokwenza ama-marshmallows, ukuwaphotha nokuwabumba njengoba uhamba.Noma ubani owenze ama-marshmallows ngaphambili uzokwazi ukuthi kunzima kakhulu ukwenza ama-marshmallows amakhulu, aqinile, futhi okufanayo kuya kwinqubo yokudonsa i-wafer, lapho ijubane lokujikeleza nokulawula izinga lokushisa lithinta ikhwalithi ye-wafer.Ngenxa yalokho, usayizi omkhulu, izidingo zejubane nezinga lokushisa ziphezulu, okwenza kube nzima nakakhulu ukukhiqiza iwafa yekhwalithi ephezulu engu-12" kune-wafer engu-8".

Ukuze kukhiqizwe ilucwecwana, umsiki wedayimane ube esesetshenziselwa ukusika isinkwa esilucwecwana sivundlile sibe amawafa, abese epholishwa ukuze akhe amawafa adingekayo ekwenzeni ama-chip.Isinyathelo esilandelayo ukupakisha izindlu noma ukukhiqizwa kwama-chip.Uyenza kanjani i-chip?

2. Ngemva kokuziswa ukuthi ayini ama-silicon wafers, kuyacaca futhi ukuthi ukukhiqiza ama-IC chips kufana nokwakha indlu ngamabhulokhi e-Lego, ngokuwapakisha ungqimba phezu kongqimba ukuze wakhe umumo owufunayo.Kodwa-ke, kunezinyathelo ezimbalwa zokwakha indlu, futhi okufanayo kuya ekwenzeni i-IC.Yiziphi izinyathelo ezihilelekile ekwenzeni i-IC?Isigaba esilandelayo sichaza inqubo yokwenziwa kwama-chip e-IC.

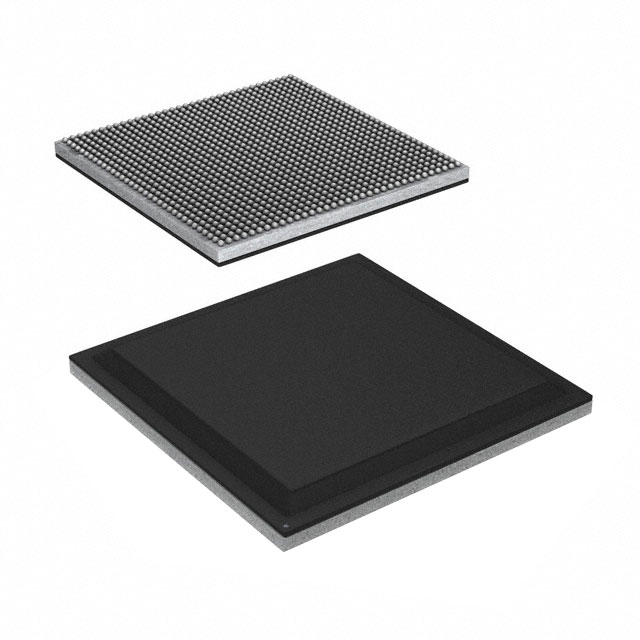

Ngaphambi kokuthi siqale, sidinga ukuqonda ukuthi iyini i-IC chip - IC, noma Integrated Circuit, njengoba ibizwa kanjalo, iyinqwaba yamasekhethi aklanyiwe ahlanganiswa ngendlela estakiwe.Ngokwenza lokhu, singakwazi ukunciphisa inani lendawo edingekayo ukuxhuma ama-circuits.Umdwebo ongezansi ubonisa umdwebo we-3D wesekethe ye-IC, ebonakala sengathi yakheke njengemishayo namakholomu endlu, enamathiselwe enye phezu kwenye, yingakho ukukhiqizwa kwe-IC kufaniswa nokwakha indlu.

Kusukela esigabeni se-3D se-IC chip eboniswe ngenhla, ingxenye eluhlaza okwesibhakabhaka emnyama ngezansi iyiwafa eyethulwe esigabeni sangaphambilini.Izingxenye ezibomvu nezinombala womhlaba yilapho kwenziwa khona i-IC.

Okokuqala, ingxenye ebomvu ingafaniswa nehholo eliphansi lesakhiwo eside.Indawo yokwamukela izivakashi esitezi esiphansi iyisango eliya esakhiweni, lapho kutholwa khona ukufinyelela, futhi ngokuvamile lisebenza kakhulu mayelana nokulawula ithrafikhi.Ngakho-ke kuyinkimbinkimbi kakhulu ukwakha kunezinye izitezi futhi kudinga izinyathelo ezengeziwe.Kumjikelezo we-IC, leli hholo liwungqimba lwesango elinengqondo, okuyingxenye ebaluleke kakhulu yayo yonke i-IC, ehlanganisa amasango anengqondo ahlukahlukene ukuze kwakhe i-IC chip esebenza ngokugcwele.

Ingxenye ephuzi ifana nephansi elivamile.Uma kuqhathaniswa nesitezi esiphansi, ayiyona inkimbinkimbi futhi ayishintshi kakhulu ukusuka phansi kuya phansi.Inhloso yalesi sitezi ukuxhuma amasango e-logic esigabeni esibomvu ndawonye.Isizathu sesidingo sezendlalelo eziningi kangaka ukuthi kuneziyingi eziningi kakhulu okufanele zixhunywe ndawonye futhi uma ungqimba olulodwa lungakwazi ukuthwala zonke izifunda, izingqimba eziningana kufanele zipakishwe ukuze kuzuzwe lo mgomo.Kulokhu, izendlalelo ezihlukene zixhunywe phezulu naphansi ukuze kuhlangatshezwane nezidingo zezintambo.